GAS DIRECT INJECTION

ENGINES & SERVICE

Gas Direct Injection or GDI is not necessarily a new technology, as its first automotive appearance was in 1952 in 1955, it was utilized in Mercedes-Benz 300SL passenger car. The GDI engine is certainly here to stay, as manufacturers are mandated to meet stringent fuel economy standards, and emission regulations. Such standards did not exist when the internal combustion engine was invented.

Gasoline direct injection (GDI) began market penetration in cars in 2007 and in light trucks in 2008. By 2016, the market share for GDI was 50.7% for cars and 43.2% for light trucks.

Source: U.S. Environmental Protection Agency, Light-Duty Automotive Technology, Carbon Dioxide Emissions, and Fuel Economy Trends: 1975 through 2016, EPA-420-R-16-010, November 2016.

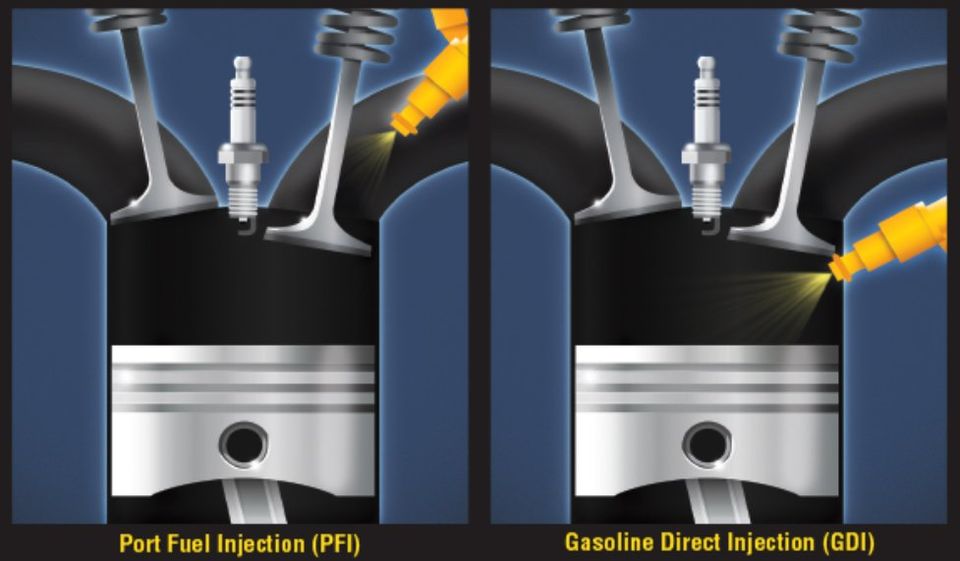

To understand and appreciate the pros, cons and service requirements of the GDI engine, we first need to understand the operation differences between the GDI engine and the Port Fuel Injection engine (PFI).

Understanding Port Fuel Injection (PFI) & Gasoline Direct Injection (GDI)

GDI engines

are offered by most vehicle manufacturers today. When compared to conventional Port Fuel Injection (PFI) systems, the most notable difference with Gasoline Direct Injection (GDI) engines is where the fuel enters the system. With a Port Fuel Injection system, fuel enters through the air intake and sprays on the back of the intake valves. Refer to Figure 1.

With a Gasoline Direct Injection system, fuel enters where the combustion chamber is the hottest; right on top of the pistons, inside the cylinders bypassing intake valves. By doing so, fuel does not spray on the back side of the intake valves as is done with the Port Fuel Injection systems. This process aids in helping keep the intake valves clean using the detergent packages already found in gasoline. The “pour in tank” additives will not address this issue, as the fuel would never contact the back of the valve area where the carbon builds up. It is important to note that a fuel additive is essential to maintain the fuel injectors themselves, as it is exposed to high temperatures and carbon fouling inside of the cylinder. This fouling of the injectors causes uneven dispersion of fuel and or limited fuel flow and ultimately costly servicing or repairs.

(FIGURE 1)

GDI Pros:

- Reduced emissions.

- Increased fuel economy: Approximately 15 to 20 % improvement by utilizing more precise air to fuel ratio control resulting in leaner burn engines. By placing the injector inside the cylinder, the engines computer gains even more precision control over the amount of fuel injected into the intake cycle to create an optimized explosion with very little wasted fuel and increased power. Such control also reduces the amount of fuel used during times when the vehicle is idling, coasting, or decelerating.

- Deliver power & performance: By incorporating efficient intake systems, high compression and in some models turbo chargers.

GDI Cons:

- When fuel is no longer washing the intake valves on the way into the cylinder, small amounts of dirt from intake air and blowback carbon from the crankcase inhalation system build up and burn onto the intake walls. The result is carbon deposits forming on the valves, cylinder heads, and injectors, and that’s where the trouble begins. Over time the carbon buildup on the intake valves reduces the air flow to the cylinders, which reduces torque, horsepower and diminishes fuel economy. The carbon deposits on the cylinder in cylinder head can cause pre-ignition, rough starting, and rough idling as well as foul spark plugs and misfire codes.

- Piston Ring Sludging: Oil thickens form gasoline blow by. (Read “Low Tension Piston Rings”)

By not taking OEM recommendations seriously when providing care for GDI engines, you can single-handedly set these vehicles on a fast track for many operational and performance issues.

Low Tension Piston Rings

In order to reduce frictional drag energy loss and increase fuel efficiency, gasoline direct injection (GDI) engines use thinner and lighter piston rings, called low tension piston rings. These piston ring tensions in older port fuel injection (PFI) engines used to be as high as 30 psi. New PFI and GDI engines can have more than a 60 percent reduction in sealing pressure on the cylinder walls, yet new PFI and GDI engine compression ratios have increased from 9:1 to as high as 14:1. These higher compression ratios dramatically increase cylinder compression and the overall pressure for fuel ignition.

This increase in pressure creates more force on the low-tension piston rings. Piston rings are supposed to prevent fuel and combustion gases from “blowing down” between the piston and cylinder wall, and oil from moving up into the cylinder. Low-tension piston rings have a greater tendency to allow blow-by of crankcase contamination therefore, compromising lubrication and promotes oil degradation.

Degraded engine oil is more susceptible to oxidation, which can cause engine oil thickening. When the engine oil thickens due to oxidation, it provides even more resistance against the low-tension piston rings. As oxidation progresses, sludge formation can occur.

When sludgy, contaminated oil starts lubricating the rings and since because of the low-tension piston rings having such low spring force, they are less capable of pushing back against deposits that may form around them. Eventually deposits will impede the rings outward expansion to seal the cylinder wall, which will allow even more fuel and combustion gases to enter the crankcase. Or, vice versa, stuck rings can promote oil consumption and intake deposit formation due to engine oil moving up into the cylinder and into the intake.

While new PFI and GDI engines are known for efficiency, the constant struggle between low tension piston rings and high operating pressures will eventually erode fuel efficiency and diminish horsepower.

The drawback to this system is its inability to maintain reasonable levels of intake valve deposits under certain conditions over time.

Within 6,500 – 8,000 km of driving; our vehicles engine begins to lose responsiveness and efficiency due to these deposits. As deposits form in the fuel system, manifold valves, combustion chamber, piston crowns, oxygen sensor and catalytic convertor; some of the things you may notice in your vehicle are; rough idle, stalling, hesitation, loss of power, decrease in fuel economy, and increase in emissions. These conditions can lead to expensive repairs such as walnut blasting, tune ups, diagnosis and sensor replacements.

Oil Volatility

Some consumers and technicians think if they change their oil before the manufacturers specifications with conventional oil (on GDI engines), that they are preventing problems and saving on the expense of having to purchase synthetic oil. The reality is that they could be making the problem worse.

Most conventional oils have high volatility numbers. If an oil has a high volatility number, it vaporizes more quickly when exposed to heat when compared to synthetic oil. This means that the oil can become thicker over time and won’t lubricate as well. It also means that there is a greater volume of oil vapor that the PCV system must process. These vapors can be loaded with hydrocarbons and stick to the intake valves, causing a carbon deposit problem. Synthetic oils have much lower oil volatility. This reduces the amount of oil vapor and the possibility of carbon deposits forming on the intake valves.

Maintenance is Everything

If your long-term plans are to include a vehicle equipped with a GDI engine, We can help, by incorporating sound maintenance practices on your GDI engine that are geared to keeping carbon build up to a minimum.

Consider the following:

- Using an oil that contains less than 7% volatility:

(lower the percentage the better). For example, Amsoil 5W30 is rated at 4.9%. The Noack volatility test, determines the evaporation loss of lubricants in high-temperature service. As the lighter hydrocarbon portion of the engine oil evaporates, the viscosity of the remaining oil increases, contributing to poor circulation, reduced fuel economy, increased oil consumption, wear and emissions.

- Installing a synthetic oil filter:

Synthetic oil filters feature advanced synthetic media that traps and holds a greater amount of small, wear-causing contaminants compared to conventional oil filters, helping reduce engine wear and compliment and improve the overall benefits of synthetic engine oils.

- Using a safe, non-solvent, ether-based oil system cleaner:

To remove sludge and clean cooling port contaminants.

- Using an effective carbon removing, vacuum intake cleaning service.

- Using an effective fuel treatment and stabilizer.

- Replacing the positive crankcase ventilation (PCV) valve where applicable.

- Using a top-quality detergent fuel.

A total fuel system cleaning service is recommended every 24,000 km on gasoline applications and 48,000 km for diesel applications. If you notice changes in your vehicle such as; rough idle, stalling, hesitation, loss of power, decrease in fuel economy, and increase in emissions; talk to our knowledgeable staff at Liberty Lube about the “Smart Blend 2 Step Fuel System” Service. Some of the direct benefits of this service are;

- Removes carbon deposits

- Cleans fuel pump, lines and injectors

- Cleans intake valves and compression chamber

- Cleans oxygen sensors

- Improves power and performance

- Helps return compression to factory levels

- Reduces emissions

- Helps eliminate rough idling, engine knock and pinging

- Eliminates hydrostatic engine lock guaranteed

Ask our staff during your next visit on how we can bring back your engines power and responsiveness!