ENGINE OIL FILTERS

As the name implies, it is a filter designed to remove contaminants from your engine oil. Most oil filters look simple but they are the object of continuing research and development to make them work better.

The “spin on” oil filter resembles a metal can that houses varying types of filter media. These are the materials that capture organic or inorganic contaminants as the oil flows through. Organic contaminants include bacteria and oxidized petroleum that forms sludge. Inorganic contaminants consist of dust that is ingested into the engine (via the engine air intake and air filter) along with trace amounts of wear metals from bearings, cylinder walls and other internal parts.

Oil Filter

It is an integral part on the engine consisting of a media (typically a cellulose fiber) designed to remove contaminants from your engine oil. Most oil filters, although simple, have been continually developed for improvement. The filter media over the years has changed from steel wool, wire mesh, metal screens and fabrics in the early years to using cellulose and now full synthetic micro-glass filter media.

The “spin on” oil filter resembles a metal can that houses varying types of filter media. These are the materials that capture organic or inorganic contaminants as the oil flows through. Organic contaminants include bacteria and oxidized petroleum that forms sludge. Inorganic contaminants consist of dust that is ingested into the engine along with trace amounts of wear metals from bearings, cylinder walls and other internal parts.

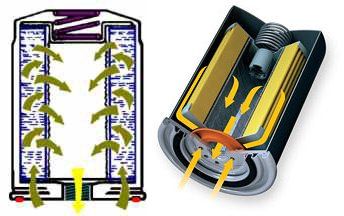

HOW IT WORKS:

Proper motor oil is essential to the proper performance, efficiency and maintenance of your vehicle’s engine. The right motor oil will protect your engine by;

- Cleaning the engine.

- Reducing friction and minimizing wear.

- Removing heat.

- Preventing rust and corrosion.

- Suspend wear particles.

- Suspend soot that forms as a result of combustion.

Some contaminants of motor oil go into suspension and some are chemically grabbed by the additives. Acting by itself, oil would eventually become saturated with contaminants and allow the internal parts to wear.

Oil is pumped from the oil sump by the oil pump, through the oil filter where debris is contained and then distributed by oil passages throughout the engine to the bearing surfaces that need lubrication. Other less critical areas that do not need pressurized oil are lubricated and cooled by oil splash, for example: the valve stems and valve guides. Refer to Figure 1.

Internal Oil system & Flow of a V-8 Engine

Base Gasket

The base gasket on a “spin on” oil filter performs two functions. First, it creates a seal between the filter and the engine block to prevent pressurized oil from leaking out. Secondly it helps secure the filter to the engine block by keeping tension on the filter threads.

Some vehicles use a “cartridge” oil filter which essentially, is only the “inners” of a spin on oil filter without the can. They contain an “O” ring type of gasket to perform a similar function as the “spin on” filter gasket. It is located on the “cap” or cover for the cartridge filter.

The operation of the filter is the same, however; the re-usable outer housing is usually held to the engine by mounting bolts so that the housing does not depend only on the base gasket tension.

The base gasket is therefore the most important part of the spin on oil filter design. The gasket will deteriorate with time, more so with mileage and will either harden or soften. In either case the gasket tension that holds the filter to the engine is relieved and will result in oil loss.

Synthetic Oil Filters

As engine technology advances and the synthetic oil which they require, so has the engine oil filter. Oil change intervals have increased due engine design and synthetic oil engineering; yet, most people have been using a conventional oil filter. The benefits of that conventional oil filter have diminished before the vehicles oil change interval and or the life span of the engine oil used.

The media construction of a typical conventional oil filter Is cellulose fibers (essentially what paper is made from). These conventional filters were designed to last up to 5000KM.

Synthetic oil filters

have three key advantages;

Filtering media

– Built with enhanced high performance, synthetic, micro-glass media, filter cartridge and steel centre tube, excellent contaminant holding capacity to compliment and improve the overall benefits of modern synthetic engine oils.

Filter Shell

– Exceptional durability and burst strength.

Anti-Drainback Valve

– Upgraded anti-drain-back valve constructed of synthetic silicone materials, provides outstanding protection during longer change intervals.

Gasket

– Made from high temperature nitrile for increased longevity and durability.

Installing a long life, synthetic oil filter will outperform conventional oil filters in trapping and removing contaminants and any “sludge” in the circulating engine oil, reducing the probability of deposits forming on the engine parts and cooling ports throughout. Use a synthetic oil filter with your next oil change to compliment and improve the overall benefits of using modern synthetic engine oils or when its common to exceed your vehicles oil change interval.